- Home

- Product Pages

- Clips and Accessories

SSTB and SSDB bypass clips

The Super Stud Double Bypass and Triple Bypass clips are used to support exterior wall studs that extend past a roof or floor. The short leg is connected to the edge of the slab or perimeter beam, and standard #12 screws inserted through the patented Glide Plate™ hold the slotted leg of the clip to the exterior wall stud. This allows for up to 3″ of total vertical movement of the floor or roof without any additional axial load on the stud.

Product Attributes

- Glide Plate™ allows the use of ANY #12 hex-head or pan-head screw: no special “shouldered” screws required.

- Heavy-duty construction with thicker steel provides some of the best capacities in the industry for bypass slide clips.

- No need for the installer to “back off” screws to prevent clamping action: Glide Plate™ allows for screws to be driven fully, saving time and labor.

- Reversible – doesn’t matter which way the stud is turned.

- Strength and durability: Both Glide Plate™ and clip are made with prime 12 gauge G90 galvanized ASTM A653 steel, with a minimum 50 ksi yield.

- 3½” tall slots – the tallest in the industry – allow a full 3″ of free movement.

- Glide Plate™ provides a full ½” of bearing along each slot. The Glide Plate™ locks screws together to work as a unit distributing the load and reducing the likelihood of individual screw shear. Even if one or more screws are stripped, the Glide Plate™ allows the clip to perform almost as if no screws were stripped.

- All holes are pre-punched, and clip is pre-assembled with Glide Plate™ taped to center position of slot.

- Embossed guide marks on Glide Plate™ allow for perfect alignment at the top, middle, or bottom of slot.

Suggested Detail for Installation

Allowable Design Loads

Double & Triple Bypass Clips covered by US patent 6213679

Deflection Clips and Accessories

Limiting deflection of a curtainwall is critical to the performance of the finished system, sealants and components anchored to the framing system. Super Stud’s Curtainwall Deflection Solutions provide lateral support for curtainwall systems. They are one of the highest-tested load capacities available, and supply direct attachments to web and support. Most clips are reversible and compatible to both welding and mechanical connections.

Clip Comparison Chart

Allowable Design Loads

Curtainwall Vertical Deflection Bypass Clips

- Super Stud Triple Bypass (SSTB) and Super Stud Double Bypass (SSDB) clips with GlidePlate™ Technology

- Super Stud Deflection Strut (SSDS 1600)

Head of wall clips

Fixed Clip Products (No Deflection)

- Cut to length clip angles – Available Upon Request

- Pre-drilled clip angles – Available Upon Request

- Utility Angles (10′ lengths) – Available Upon Request

F-Track Corner Framing

F-Track 20EQ Interior Framing Product for Corners & Tight Spaces

Super Stud F-Track is an economical option for horizontal corners such as soffits, drop-ceilings, box-outs, and other drywall features that require a smooth, straight, corner intersection at 90 degrees. The single-piece F configuration allows for both horizontal and vertical framing attachment: without having to build up double tracks or track and angle members. The double thickness in both of the large hems and the vertical inner flange provides rigidity and strength, which helps with both installation and long-term system stability and resiliency. The hemmed edges on the inner and outer flanges give added strength and safety, and complement our line of the EDGE™ stud and track framing products.

And, like all Super Stud steel products, F-Track is Made in the USA, with zinc-coated steel: minimum 25% recycled content, and 100% recyclable.

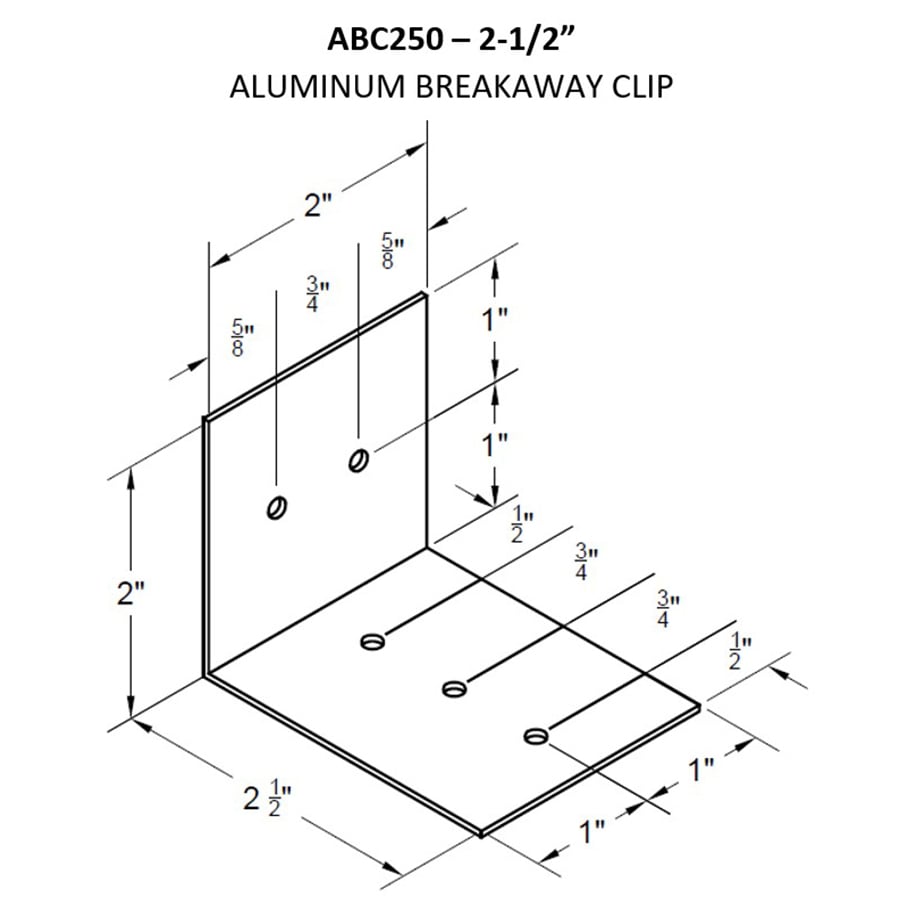

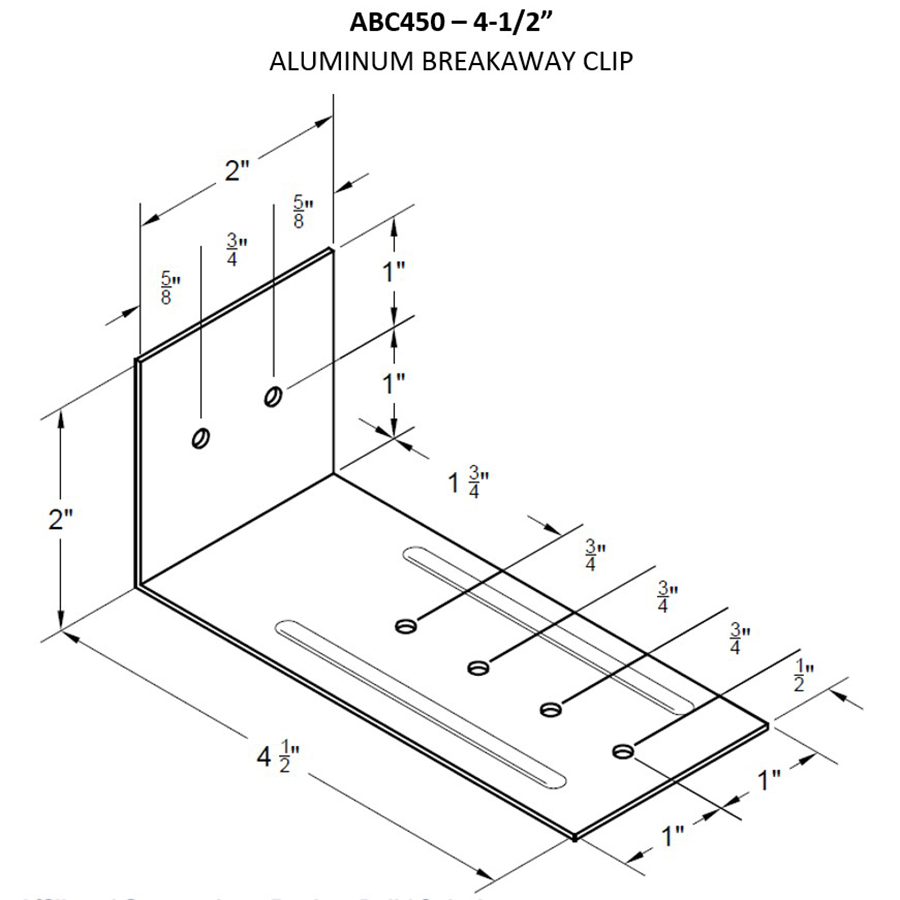

Aluminum Breakaway Clips

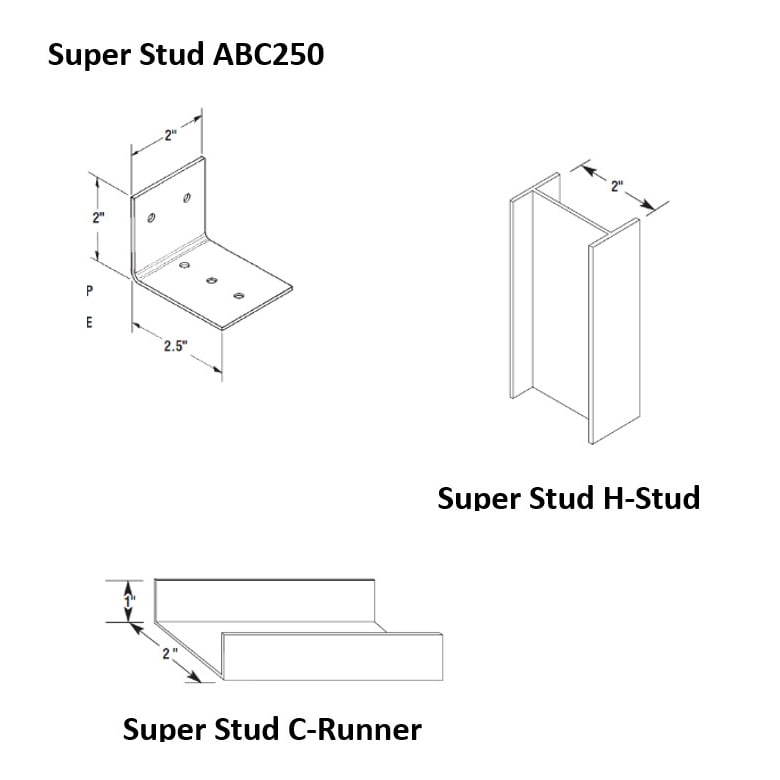

Aluminum Breakaway Clip (ABC250 & ABC450 Clips) for Area Separation Wall (ASW) Assemblies

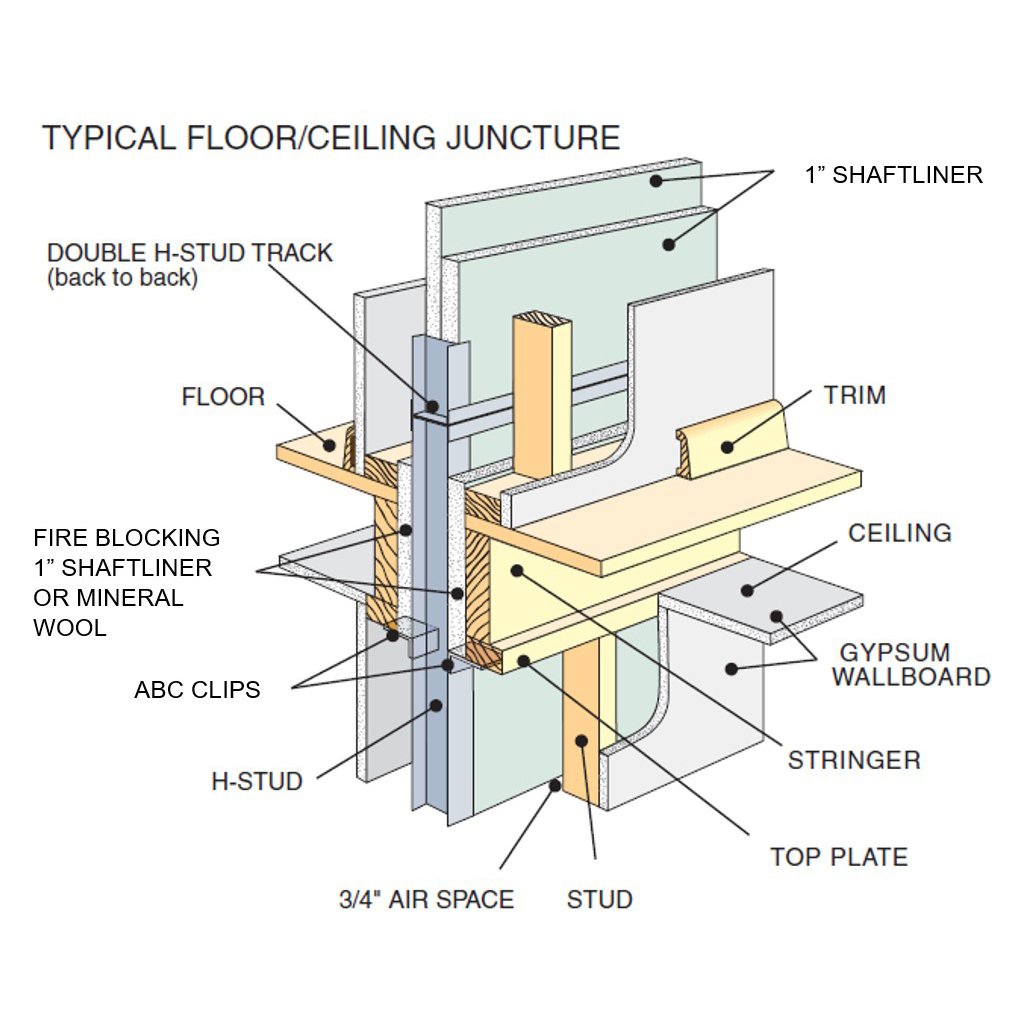

Aluminum breakaway clips are used on both sides of area separation walls, for support by the adjacent structure. Clips are designed so that when a fire occurs, the clips on the fire side of the wall will melt, allowing the burned structure to fall away without dragging down the protective area separation wall. This maintains protection of the adjacent building, no matter which side of the wall is exposed to fire.

Aluminum Breakaway Clip Product Description:

Super Stud clips are the most common configuration for Area Separation Wall assemblies. Clips are made of construction grade aluminum sheet, with pre-drilled holes in both flanges. Holes are 5/32” diameter (0.156” or 4 mm) and placed as shown in diagrams.

Holes are 5/32” diameter (0.156” or 4 mm) and placed as shown.

Product Data:

Product Category: Nonstructural Area Separation Walls (typically specification section 09 22 16)

Yield Strength: 21 KSI Tensile Strength: 22 KSI

Material: Aluminum 3003-H14

Temperature Range: Heat Softenable at 1000 Degrees Fahrenheit

Hole Size: 5/32” (4 mm)

Thickness: 0.050” (min) 0.052” (design)

ASTM and Code Standards:

International Building Code (IBC) 2006 - 2021

Sheet Aluminum: Aluminum Association (AA) 3003-H14

UNS A93003, ISO AlMn1Cu

Members and Tolerances: ASTM C645

Meets ASTM C1007 when installed properly in structure

Use & Installation Instructions:

Important:For a detailed description of clip requirements and wall construction, please consult the appropriate Underwriters Laboratories (UL) design or gypsum company requirements for Area Separation Walls.

Installation:- Once the first level of wall is installed with double liner panels, H-studs, and C-runners, attach all H-studs and vertical C-runners to adjacent framing with aluminum breakaway clips.

- Clips attaching H-studs and vertical C-runners to adjacent framing on both sides require attachment to the H-stud and C-runner with one 3/8” Type S screw.

- Clips attaching H-studs and vertical C-runners to adjacent framing on only one side and with exterior exposure on the other side require attachment to the H-stud and C-runner with two 3/8” Type S screws.

- Attachment to the adjacent framing is with one 1-1/4” Type W or Type S screw.

- Wall heights are dictated by the specific fire-rated assembly.

- At least one clip is required at each floor line at each vertical steel element of the area separation wall.

Clip Angles

Clip Angles serve a variety of functions in the construction of a steel framing system. They may be used to make attachments between framing members or to transfer gravity and lateral loads from a stud to the primary frame.

Product Data and Ordering Information:

Dimensions:

Super Stud can manufacture clip angles to any dimension. Please call our Customer Service at 732-662-6200 for details.

Design Steel Thickness:

The structural properties and load tables were prepared using the following design steel thicknesses:

20 gauge: 33 mils, 0.0346 inch

18 gauge: 43 mils, 0.0451 inch

16 gauge: 54 mils, 0.0566 inch

14 gauge: 68 mils, 0.0713 inch

12 gauge: 97 mils, 0.1017 inch

ASTM and Code Standards:

Super Stud structural framing components are zinc coated (galvanized) in accordance with ASTM A653

and ASTM A1003. 25 and 20 gauges are coated with ASTM A1003 G40 galvanization; 18 gauge and greater

are coated with ASTM A1003 conforming G60 galvanization. Super Stud can also fulfill requests for G-90

coatings which provide 50 percent more zinc protection.

In conformance with the AISI Specification and AISI-S200-07, the actual delivered base steel thickness,

individual measurement, must not be less than 95 percent of the inch values listed above.

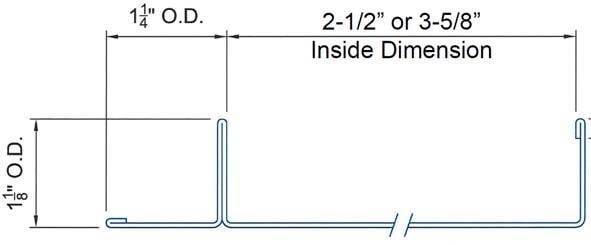

Cold-Rolled Channel CRC

AISI Nomenclature: 150U050-54

Cold Rolled Channel has a number of uses ranging from cross furring and hangers in both plaster and gypsum wallboard ceilings to mechanical bridging for stud walls. Super Stud CRC is available in 54mil (16 ga.) with a 1/2" flange and web depths of 3/4", 1.5”, and 2”.

Product Data and Ordering Information:

Steel Thickness: 54 mil (16 ga.)

Standard Lengths: 10 and 16 Ft.

Design Thickness: 0.0566”

Minimum Thickness: 0.0538"

Flange width: 1/2"

Web Depth: available in 3/4", 1.5”, and 2”

ASTM and Code Standards:

International Building Code (IBC) 2006 - 2018

Sheet Steel: ASTM A1003 and ASTM A653

Galvanized Coating: ASTM A653

Members and Tolerances: ASTM C955

Meets ASTM C754 and C1007 when installed in structure

3rd Party Certification: Manufacturing verified and inspected by Home Innovation Research Labs, Inc.

Flat Strap

Flat Strap has a variety of uses that include wall bridging and backer plates to facilitate the installation of handrails and fixtures.

Product Data and Ordering Information:

Flat Strap Steel Thickness: 18 to 118 mil (25 to 10 gauge)

Standard Width: 2”, 4” and 6”

(Custom widths available upon request)

Standard Length: 10 Ft.

ASTM and Code Standards:

Super Stud products comply with the applicable provisions of the following:

International Building Code (IBC) 2006 - 2018

Sheet Steel: ASTM A1003 and ASTM A653

Galvanized Coating: ASTM A653

Tolerances:

Nonstructural: ASTM C645, AISI S220

Structural: ASTM C955, AISI S240

Meets ASTM standards C754 (nonstructural) and C1007 (structural) when installed properly in structure.

3rd Party Certification: Manufacturing verified and inspected by Home Innovation Research Labs, Inc.

Furring Channel

Download Submittal for Furring Hat Channel 7/8 inch

Download Submittal for Furring Hat Channel 1 1/2 inch

Download Submittal for Furring Channel 7/8 inch 18 mil (25 gauge) with Hemmed Edge

Super Stud Building Products Furring Channel (often called hat channel) provides support for sheathing, siding, and decking products in the construction of soffits, ceilings, roofs, and walls. Furring Channel is compatible for use over any of a number of different support members. Available in both 7/8” and 1 ½” depths, standard lengths for Furring Channel are 8, 9, 10, and 12 feet.

Furring Channel is shipped in bundles of ten pieces.

Product Data and Ordering Information:

Available in 7/8” and 1 ½” depths

Standard lengths: 8, 9, 10, and 12 feet.

Furring Channel is shipped in bundles of ten pieces

Special Notes:

Hemmed Leg Furring Channel is only available with a 7/8" leg and 18 mil (25 Gauge) material.

ASTM and Code Standards:

Super Stud Building Products Inc. manufactures nonstructural steel framing members, components, and accessories in compliance with American Iron and Steel Institute (AISI) and ASTM design A653, C645.

- Furring Channel is produced to meet ASTM C645.

- Galvanized sheet steel meets requirements of ASTM A924 and A1003

- Complete installation info is available on ASTM C754

Galvanized sheet steel meets requirements of ASTM A924 and A1003:

G40 standard for 25 and 20 gauge; G60 available for 20 gauge.

G60 standard for 18 and 16 gauge; G90 available for 18 and 16 gauge.

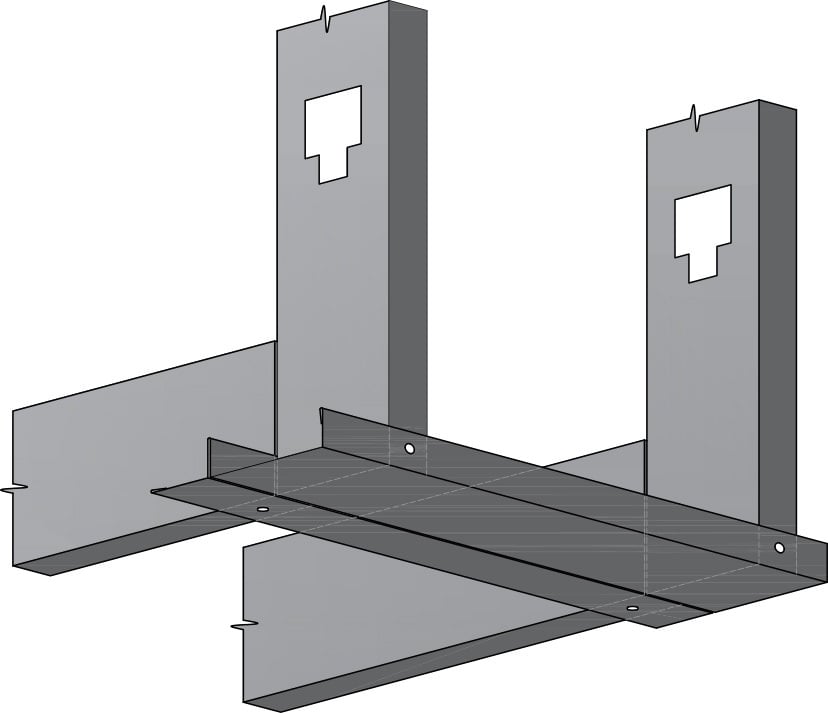

Furring Channel Clips

Super Stud metal furring channel clips are designed to support 7/8” drywall furring channels up to 33 mils to standard 1-1/2” x 54 mil (16 gauge) cold-rolled channel. These are typically installed with the cold-rolled channel (CRC) supported

to the structure above using wire or pencil-rods or straps, then the furring channel clips are used to support hat (furring) channels. Although spacing varies for various loading conditions and configurations, for typical ceilings the CRC is spaced

at no more than 48” on center (o.c.), and the furring channels are spaced at 16” o.c. Both the hat channel and the CRC snap easily into the clips, making this a faster and simpler installation that the wire-tying method. Clips can be installed

in either direction but should alternate direction along the length of the CRC to prevent rotation. These clips facilitate fast installation of drop ceilings and large soffits.

Furring channel clips have an allowable working load of 50 pounds, with an ultimate load of 200 pounds. This is for the clip connection itself and does not consider span capacity of the furring channel or CRC, or the pullout strength of screws in the furring channel.

Product Data and Ordering Information:

Material: 0.134” bare steel thickness galvanized wire

Coating: Zinc: hot-dip galvanized

Packaging: 500 pieces per box

ASTM and Code Standards:

Codes and Standards: ASTM C754

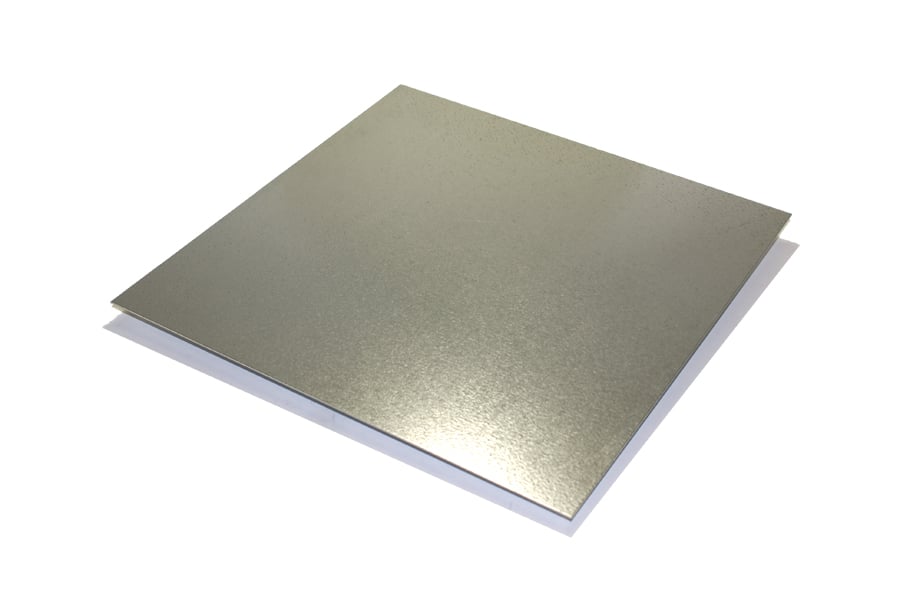

Gusset Plates

Gusset plates are available in all structural thicknesses, widths, and lengths up to 10 feet. They may be used for truss construction, ends of diagonal strap X bracing, anchors at the base of walls, force transfer locations at floor-wall or floor-roof intersections, or other locations where flat steel is required.

Product Data and Ordering Information:

Available lengths: from 1” to 120”

Available widths: from 1” to 48”

Available Coatings: G60, G90

ASTM and Code Standards:

International Building Code (IBC) 2006 - 2018

Sheet Steel: ASTM A1003 and ASTM A653

Galvanized Coating: ASTM A653

Members and Tolerances: ASTM C955

Meets ASTM C1007 when installed properly in structure

3rd Party Certification: Manufacturing verified and inspected by Home Innovation Research Labs, Inc.

Header Jamb and Cripple Clip

AISI Nomenclature: HJC

The Header, Jamb, and Cripple Clip (HJC)

-Universal Clip for Jamb Attachment, Header Stiffening/Support, and Cripple Stud Attachment

-Slotted to Accommodate Header Return Stiffening Lips

-“Center Rib” for Increased Strength

-1” Legs allow “Throat” or alternate “Back to Back” Cripple Attachment

-Utilize Single “Jamb” Stud Profile as Header Framing

-Flush Profile Installation no Buildup, Cracking or Excess “Floating” Around Openings to Level

-Eliminate “Box” Header Assemblies and Custom Shaped Profiles

-No Field Modification to Cut, Grind, Form, and or Buildup of “Tabbed” Ends

-Eliminate “Cripple Track” and Buildup Above Header Profile

-No “Pre-Insulation” - Avoid Insulation Exposure and Moisture Retention Issues

Product Data and Ordering Information:

54 mil (16 Ga) - 2.00” to 3.50” Flange Widths

43 mil (18 Ga) - 1.25” to 1.625” Flange Width

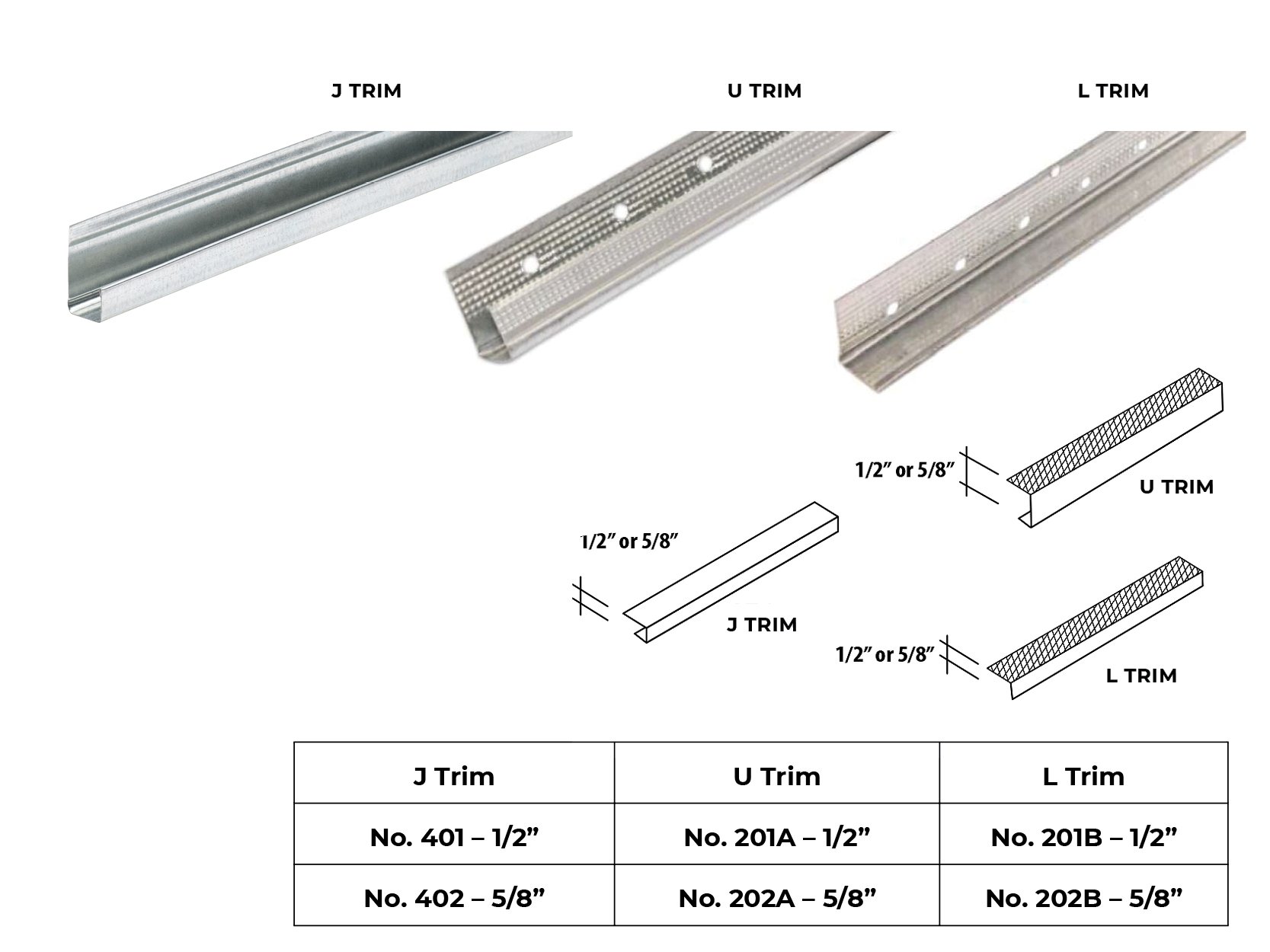

J L and U-Trims

J, L and U Trim are metal trim accessories used to protect free edges of gypsum wallboards ranging in thickness from 1/2” to 5/8” among a variety of uses.

Super Stud metal J, L and U-Trims is used at the termination of a gypsum board finished wall or ceiling. This may be at a door or window opening, at a transition to a different type of finish, or at any edge where a clean, straight, smooth edge is required. Super Stud Trim products come in custom-fit cardboard packaging, to protect product edges from shipping damage. Super Stud trims are made in the USA, with zinc-coated steel: minimum 25% recycled content, and 100% recyclable.

J-Trim

The short leg of Super Stud J-Trim is hemmed for a safe, clean, smooth edge, and both legs are angled for a tight grip on gypsum or other sheathing. The long leg has a slight rib at its base to act as a screed for any finishes that are applied, and the outer edge of the long leg has a small bevel for a smooth tight fit.

L-Trim

The short leg of Super Stud L-Trim is hemmed for a safe, clean, smooth edge, and both legs are angled for a tight grip on gypsum or other sheathing. The long leg is knurled and perforated and specifically treated for optimal acceptance of gypsum– or chemical-based joint compounds: with maximum adhesion and minimal sag.

U-Trim

The knurled leg of our U-Trim has a smooth, dull finish, specifically treated and perforated for optimal acceptance of gypsum– or chemical-based joint compounds: with maximum adhesion and minimal sag. U-Trim may be nailed, stapled, or screwed to the gypsum, wood, or steel substrate.

Product Data and Ordering Information:

Standard Lengths include 8, 9 and 10 Ft.

Quantity per carton: 50 pieces, (1/2” and 5/8”) Trim Length: 10’-0”

ASTM and Code Standards:

Super Stud products comply with the applicable provisions of the following:

International Building Code (IBC) 2006 - 2018

Meets ASTM C754 when installed properly in structure

Sheet Steel: ASTM A1003 and ASTM A653

Zinc galvanized Coating: ASTM A653 and ASTM C645

Members and Tolerances: ASTM C645

3rd Party Certification: Manufacturing verified and inspected by Home Innovation Research Labs, Inc.

Joist Bridle Hangers

Joist hangers are installed over the top of beams or girders. Top flanges may be welded to steel support beams, or bolted/shot/pinned to other substrates. Tests of joist hangers are based on welded top flange connections. Web crippling of the joist members must be independently verified. Shallow joist hangers are available with (3) pre-punched holes each tab. When attached over cold-formed steel (CFS) girder members with minimum 2.5” flanges, use (3) screws or pins in each top tab for connection to girder.

Product Data and Ordering Information:

Standard bridle style joist hangers are made for the end support of Super Stud joist members with flanges up to 2” wide. Custom hangers are available for multiple members or larger flanges.

Available depths: 6”, 8”, 10”, 12”

Available widths: 2” (standard: for SSC, SSJ, AND SJW members) 4” for double members; custom widths also available

Strip width: 2” minimum

End bearing for joists: 2” (with joist fully seated)

Thickness:

Minimum thickness = 0.0966” (12 gauge)

Yield Strength: 50 kips per square inch (KSI) minimum

ASTM and Code Standards:

Joist hangers are galvanized in accordance with ASTM A653. Steel complies with ASTM A1003 for chemical composition and

coating. Properly constructed assemblies comply with ASTM C1007.

Resilient Channel

Download Submittal for RC1 Premier

Download Submittal for RC1 Premier - EB Metal US (New England)

Resilient channel provides a ½” offset between gypsum board and wall studs or ceiling rafters, enhancing acoustical performance and achieving higher STC ratings in wall and floor-ceiling assemblies. RC1 and RC2 have 1 ¼” attachment flanges, while RC Super has a 1 ½” flange.

Resilient channel provides a ½” offset between gypsum board and wall studs or ceiling rafters, enhancing acoustical performance and achieving higher STC ratings in wall and floor-ceiling assemblies. RC1 and RC2 have 1 ¼” attachment flanges, while RC Super has a 1 ½” flange.

RC-1 Single Leg Resilient Channel

Super Stud's' RC1 Premier™ will enhance the STC rating of your metal or wood framing project. Used as a cross-furring member, RC-1 is installed perpendicular to the framing members. Pre-punched for easy attachment with holes 2” O.C. Screws should be used to attach RC -1 to metal or wood framing as nailing is not recommended. See chart below for testing data.

RC Super™ Single Leg Resilient Channel

Super Stud RC Super will enhance the STC rating of your metal or wood framing project. Used as a cross-furring member, RC Super is installed perpendicular to the framing members. Pre-punched for easy attachment with holes 2” O.C. Screws should be used to attach RC Super to metal or wood framing as nailing is not recommended.

RC-2 Double Leg Resilient Channel

Super Stud RC-2 is typically used for ceiling applications with multiple layers of gypsum board. It also enhances the STC rating of your metal or wood framing project. Used as a cross-furring member, RC-2 is installed perpendicular to the framing members. Pre-punched for easy attachment with holes 2” O.C. Screws should be used to attach RC -2 to metal or wood framing as nailing is not recommended.

Product Data and Ordering Information:

RC1 Premier and RC 2: Design thickness: .0188” (25 GA)

Material: Grade 40 ksi minimum yield strength.

G-40 Galvanized (standard) G60 available.

RC Super: Design thickness: .023

Material: Grade 40 ksi minimum yield strength.

G-40 Galvanized (standard) G60 available.

Special Notes:

RC Super meets the resilient channel requirements of the following UL assemblies:

L521, L546, L547, L550, L558, L562, L563, L569, L570, L574, L576, L579, L589, L590, L592, L593, L598, M501, M502, M503, M506, P515, P522, P524, P531, P533, P535, P538, P541, P545, P549, P551, P552.

ASTM and Code Standards:

Super Stud Building Products Inc. manufactures nonstructural steel framing members, components, and accessories in compliance with American Iron and Steel Institute (AISI) and ASTM.

Super Stud products comply with the applicable provisions of the following:

International Building Code (IBC): 2006 – 2024

Sheet steel: ASTM A1003/A1003M; ASTM A653/A653M; ASTM A924/A924M

Galvanized coating: ASTM A653/A653M

Members and tolerances: ASTM C955; AISI S240, AISI S201, AISI S202

Meets ASTM C1007 when installed properly in structure.

Meets ASTM C645

|

Stud Spacing |

Resilient Channel |

R-13 Fiber-glass Batt |

5/8” Type X Gypsum |

STC Rating |

|

362EDS125-15 |

||||

|

24” o.c. |

No RC |

With Insulation |

1 and 1 |

51 |

|

No RC |

With Insulation |

1 and 2 |

56 |

|

|

No RC |

With Insulation |

2 and 2 |

58 |

|

|

16” o.c. |

No RC |

With Insulation |

1 and 1 |

49 |

|

No RC |

With Insulation |

1 and 2 |

53 |

|

|

No RC |

With Insulation |

2 and 2 |

58 |

|

|

362EDS125-19 |

||||

|

24” o.c. |

No RC |

With Insulation |

1 and 1 |

48 |

|

RC1 |

With Insulation |

1 and 1 |

52 |

|

|

RC1 |

With Insulation |

1 and 2 |

56 |

|

|

RC1 |

With Insulation |

2 and 2 |

60 |

|

|

16” o.c. |

No RC |

With Insulation |

1 and 1 |

46 |

|

RC1 |

With Insulation |

1 and 1 |

50 |

|

|

RC1 |

With Insulation |

1 and 2 |

54 |

|

|

RC1 |

With Insulation |

2 and 2 |

58 |

|

|

2” x 4” Wood Stud Wall |

||||

|

24” o.c. |

No RC |

With Insulation |

1 and 1 |

39 |

|

RC1 |

With Insulation |

1 and 1 |

50 |

|

|

16” o.c. |

No RC |

With Insulation |

1 and 1 |

36 |

|

RC1 |

With Insulation |

1 and 1 |

45 |

|

|

RC1 |

With Insulation |

1 and 2 |

49 |

|

|

RC1 |

With Insulation |

2 and 2 |

55 |

|

|

2” x 6” Wood Stud Wall |

||||

|

24” o.c. |

No RC |

With Insulation |

1 and 1 |

40 |

|

RC1 |

With Insulation |

1 and 1 |

51 |

|

|

16” o.c. |

No RC |

With Insulation |

1 and 1 |

37 |

|

RC1 |

With Insulation |

1 and 1 |

46 |

|

|

RC1 |

With Insulation |

1 and 2 |

50 |

|

|

RC1 |

With Insulation |

2 and 2 |

56 |

|

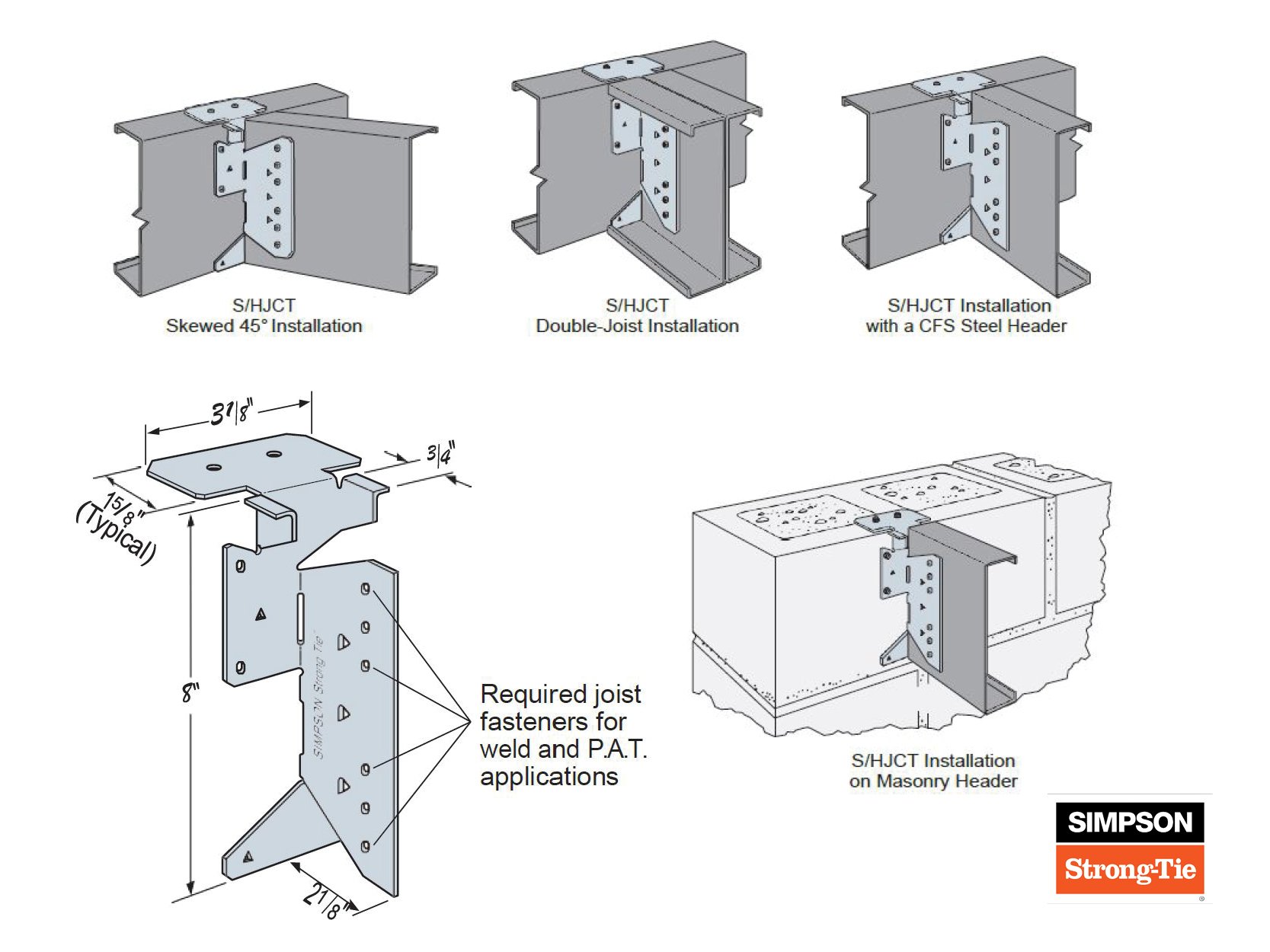

S/HJCT Steel-Joist Connectors

S/HJCT connectors are unique, skewable steel-joist framing connectors that combine strength, versatility and low installed cost. The connectors can be used with CFS headers, wood headers, steel I-beams (with welds or PAF fasteners) and masonry walls. Installed cost is minimized since these products are shear rather than bearing connectors, eliminating the need for web stiffeners. The connectors also feature horizontal tabs that facilitate top flange alignment and joist support during screw installation.

Product Data:

Material: S/HJCT—97 mil (12 ga)

Finish: Galvanized

Features:

• Uni-directional: Joist can be attached from left or right

• One size fits joists 8"through 14" deep.

• Optional holes for additional load capacity.

• Simplicity of design.

• Quick and easy installation.

• Field skewable up to 45° left or right.

Installation:

• Attach hanger with specified fasteners. Use round holes for minimum load, use round and triangle holes for maximum load.

• May be used for weld-on applications. The minimum required weld to the

top flange is 1/8"x21/2"fillet weld to each side of top flange. Consult the code for special considerations when welding galvanized steel.

• May be installed using PDPAT-62KP (0.157" x 5/8") powder-actuated fasteners. SteeI headers with thicknesses between 1/4" and 3/4" having a minimum Fy = 36 ksi. A Red (level 5) or Purple (level 6) powder load may be required to achieve

specified penetration (p). Ordering Information: The S/HJCT is sold in kits as the S/HJCT-KT and contains

five (5) connectors and (95) #14 screws.

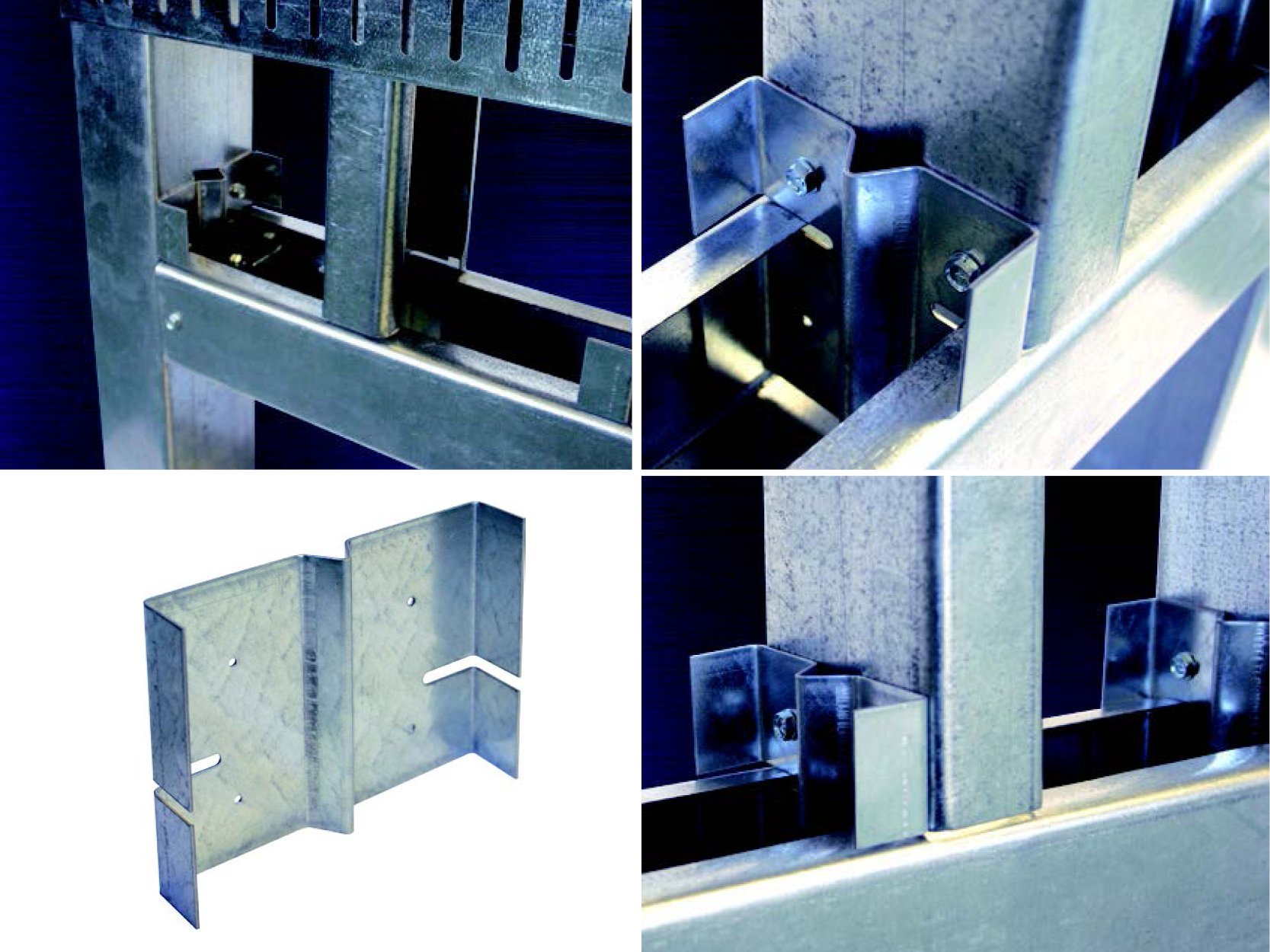

Simpson Strong-Tie® SUBH

Simpson Strong-Tie® SUBH and MSUBH wall stud bridging connectors for cold-formed steel (CFS) framing offer a compact profile that allows standard 15/8" studs to be sistered directly against adjacent studs.

Many applications require only one screw, greatly reducing labor costs and increasing productivity.

Product Data and Ordering Information:

Features:

• Tested to include stud-web strength and stiffness in the tabulated design values

• Design values ensure compliance with AISI S100 Sections D3.2.1 and D3.3 for axially and laterally loaded studs

• Flexible design solutions for web thicknesses of 33 mil (20 ga.) through 97 mil (12 ga.) and stud sizes from 35⁄8" to 8"

• MSUBH accommodates back-to-back built-up members ranging from 33 mil (20 ga.) to 54 mil (16 ga.)

Material: SUBH3.25 – 43 mil (18 ga.)

Finish: Galvanized (G90)

Installation:

• See Simpson Strong-Tie CFS Catalog, pages 54 through 56.

Codes: See page 11 for Code Report Reference Key Chart.

Ordering Information:

SUBH3.25-R150 (Bucket of 150)

SuperBead® Drywall Corner Bead

High Quality Super Bead is used in conventional gypsum wallboard installations. Super Stud corner beads provide a straight, smooth finished surface for outside corners of gypsum wallboard assemblies while it protects the corner from abuse and wear after installations. A positive attachment can be achieved with nails or screws.

Product Data and Ordering Information:

Width: 1 1/4” Flange

Length: Please specify dimensions when ordering. Lengths of 8’, 9', 10’ and 12’ are available

Packaging:

• 8’ length 63 pcs/carton 48 carton/skid

• 9’ length 56 pcs/carton 48 carton/skid

• 10’ length 50 pcs/carton 48 carton/skid

• 12’ length 42 pcs/carton 48 carton/skid

Material Thickness: 31 Gauge: 14 mils, 0.0135 inch minimum thickness

ASTM and Code Standards:

• Meets ASTM C1047 requirements for coating, properties, and manufacture.

• Steel coating meets requirements of one of the following:

• ASTM A653, G-30 minimum

• ASTM A463, Ti-40 minimum

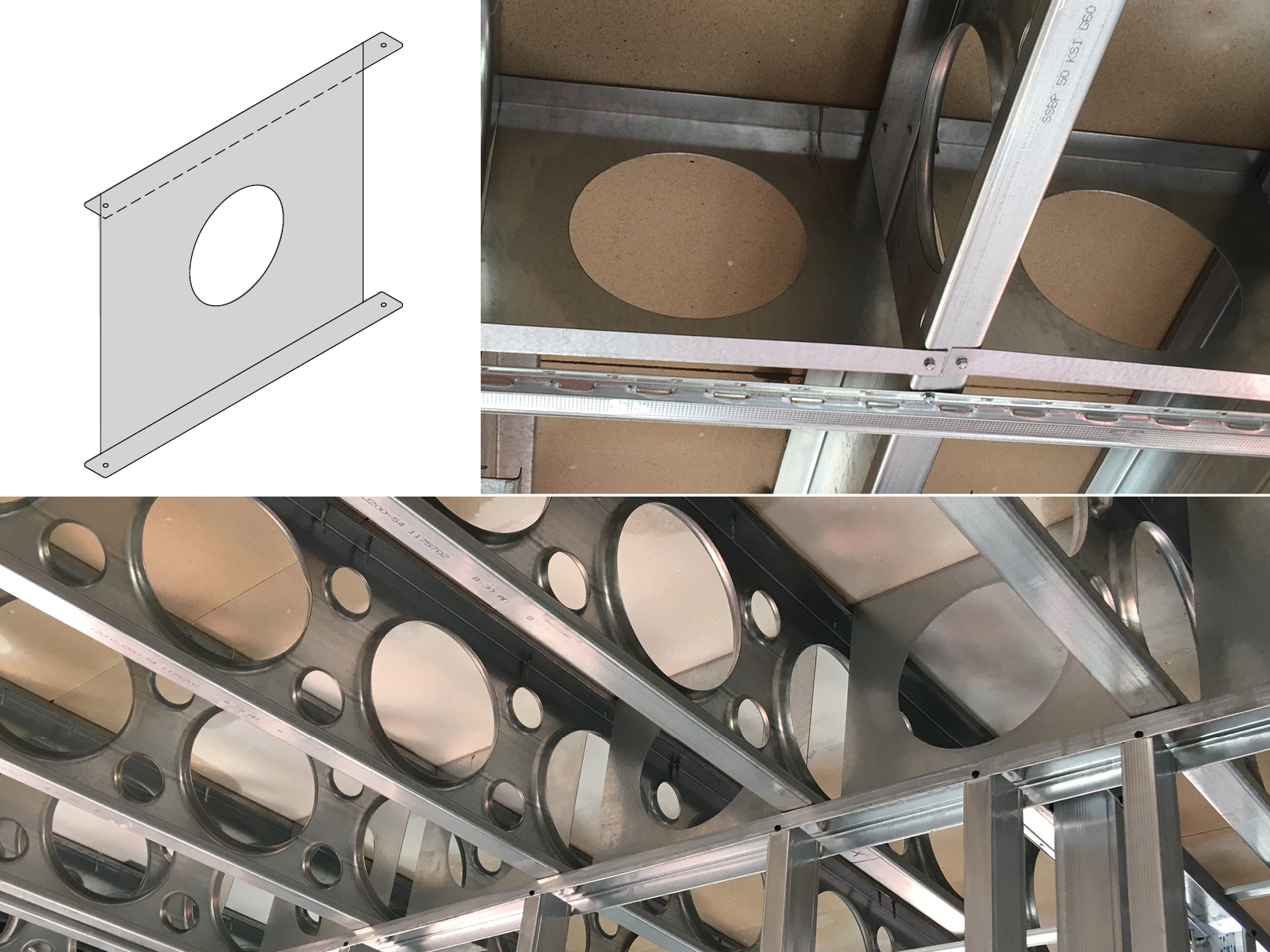

SuperJoist Blocking

AISI Nomenclature: SJB

Super Stud Joist Blocking provides bracing against twisting and horizontal movement, and when properly installed can allow joists to achieve full capacity. Each blocking

piece has an access hole to allow for utilities to pass through, and includes tabs on each end for attachment to joist flanges.

Product Data and Ordering Information:

Available Coatings: G60 (standard)

Material Notes: See table on submittal sheet for available combinations of joist depth, spacing, flange width, thickness, and yield strength

Web Depths: 8”, 10”, 12”, 14”, 16”, 18”

Joist spacing: 16” (standard) 12” available

ASTM and Code Standards:

Super Stud products comply with the applicable provisions of the following:

- International Building Code (IBC) 2006 - 2018

- Sheet Steel: ASTM A1003 and ASTM A653

- Galvanized Coating: ASTM A653

- Members and Tolerances: ASTM C955

- Meets ASTM C1007 when installed properly in structure - 3rd Party Certification: Manufacturing verified and inspected by Home Innovation Research Labs, Inc.

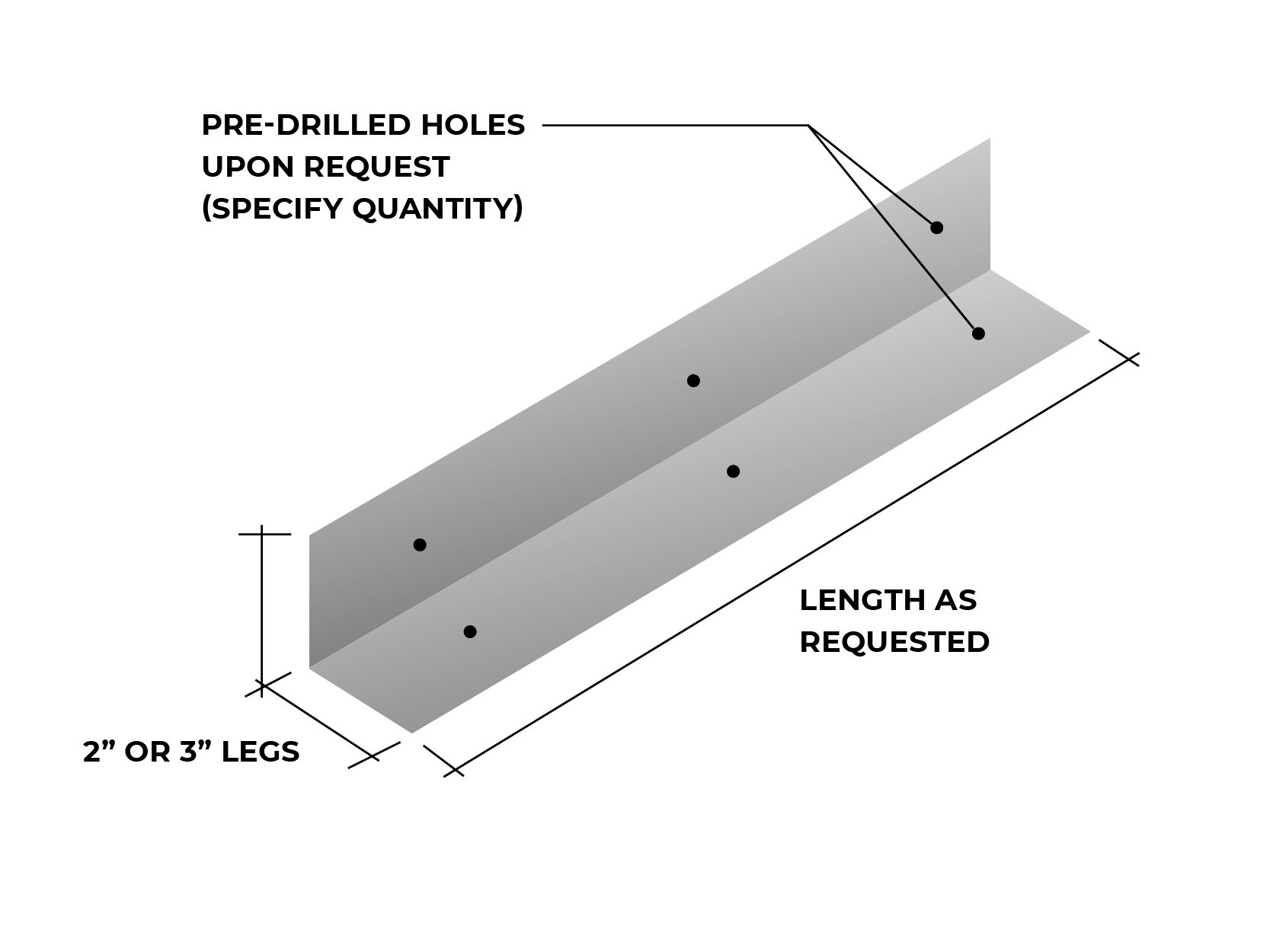

Utility Angles

Utility angles are installed at corner conditions to provide continuous support for board products. Other applications include bracing, bridging, flange restraint, blocking, support for accessories, and support for sheathing or finishes.

Our standard G40 coating is available for thicknesses up to 30 mils. For 33 mil and heavier thicknesses, standard coating is G60, with G90 coating available. Note that Utility Angles are typically NOT punched or drilled; although custom made Clip Angles are also available from Super Stud.

Product Data and Ordering Information:

Although 2” legs are shown, longer, shorter, and unequal leg angles are available upon request. Lengths are typically 10 feet, although other lengths are also available upon request.

Only 2” x 2” x 25 gauge is hemmed; other sizes have flat legs (no hem). Angle bend is typically 90 degrees; custom bends and configurations are available on request.

See also Super Stud Clip Angles for specialty clips for specific installations.

ASTM and Code Standards:

Members are galvanized in accordance with ASTM A653, G40 minimum. Steel complies with ASTM A1003 for chemical composition and coating. Members comply with ASTM C645, and properly constructed assemblies comply with ASTM C754.

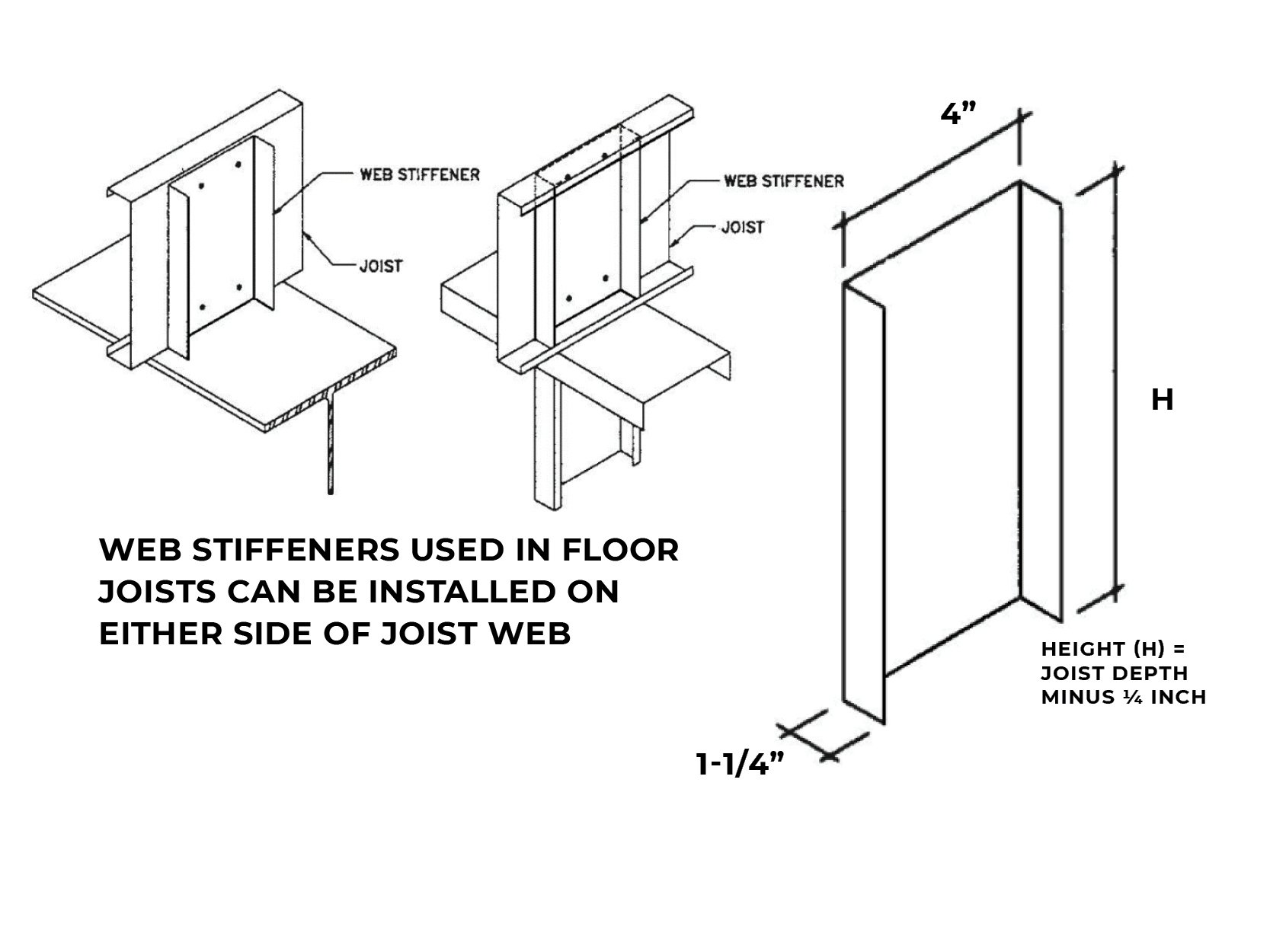

Web Stiffeners

Web stiffeners are used as a joist or header web reinforcement piece. These factory pre-cut sections are available in standard lengths to fit inside the flanges of a floor joist or built-up header.

Product Data and Ordering Information:

Web Stiffener Length Chart

Joist Depth Web; Stiffener Length:

18” (1800S); 17-3/4”

16” (1600S); 15-3/4”

14” (1400S); 13-3/4”

12” (1200S); 11-3/4”

11 ¼” (1125S); 11”

10” (1000S); 9-3/4”

8” (8000S); 7-3/4”

7 ¼” (725S); 7”

6” (600S); 5-3/4”

5 ½” (550S); 5-1/4”

4” (400S); 3-3/4”

Custom web stiffeners can be made if required for joists less than 4” deep

Thickness: 54 mil (16 gauge),

Minimum Thickness: 0.0538" minimum

Design Thickness: 0.0566"

Yield strength: 50 KSI minimum

Dimensions: 4” Web X 1-1/4” Legs

Available coatings: G60 (standard), G90

Packaging: (10) Pieces per bundle

ASTM and Code Standards:

• Structural framing is produced to meet or exceed ASTM C955

• Galvanized sheet steel meets or exceeds requirements of A653 and A1003

• Meets ASTM C1007 when properly installed in a structure

Z-Furring Channel

Z Furring facilitates the attachment of gypsum drywall to concrete or masonry walls. The depth of the furring varies to allow for the installation of insulation between the furring.

Product Data and Ordering Information:

Design Steel Thickness

The structural properties and load tables were prepared using the following design steel thicknesses:

25 gauge: 18 mils; 0.0179 inch

20 gauge: 33 mils, 0.0346 inch

18 gauge: 43 mils, 0.0451 inch

16 gauge: 54 mils, 0.0566 inch

14 gauge: 68 mils, 0.0713 inch

12 gauge: 97 mils, 0.1017 inch

NOTE: In conformance with the AISI Specifications, the actual delivered base metal thickness must not be less than 95 percent of the design thickness.

Standard Profiles:

Super Stud offers Z-Furring in web depths of 1", 1.5", 2", 2.5", and 3" as well as custom depths.

Super Stud offers Z-Furring leg lengths in standard lengths, as well as custom lengths.

Please specify dimensions when ordering. Gauges 25 through 10 available upon request. 10’ standard length.

Please note that all Z-furring will be manufactured in the shape as shown below. Dimensions of web depth and leg length will be verified upon ordering.

ASTM and Code Standards:

Super Stud structural framing components are zinc coated (galvanized) in accordance with ASTM A653 and ASTM A1003. 25 and 20 gages are coated with ASTM A1003 G40 galvanization; 18 gage and greater are coated with ASTM A1003 conforming G60 galvanization. Super Stud can also fulfill requests for G-90 coatings which provide 50 percent more zinc protection.

All Products

- Clips and Accessories

- Aluminum Breakaway Clips

- Clip Angles

- Cold-Rolled Channel CRC

- Flat Strap

- Furring Channel

- Gusset Plates

- Header Jamb and Cripple Clip

- J L and U-Trims

- Joist Bridle Hangers

- Resilient Channel

- S/HJCT Steel-Joist Connectors

- Simpson Strong-Tie® SUBH

- Solid Blocking

- SuperBead® Drywall Corner Bead

- SuperJoist Blocking

- Utility Angles

- Web Stiffeners

- Z-Furring Channel

- Nonstructural Studs

- Nonstructural Tracks

- Structural Stud and Joist

- Structural Track

- Shaft Wall and Area Separation Wall

- MSDS-SDS and Green Building