- Home

- Product Pages

- Interior Framing

The Edge™ Framing

The EDGE™ Steel Framing System features lightweight and high-strength steel combined with an innovative design that incorporates a closed triangular lip. This (US Patents: US D606211 S1, US 8,056,303 B2 Additional patents pending) system provides the framer with the safest installation environment in the industry. The EDGE also delivers increased wall heights, while still meeting ASTM standards for screw retention and penetration. Combine those features with industry leading STC ratings and The EDGE is hard to equal. The EDGE is the safest drywall stud the building industry has to offer, designing out hazards in the field.

The EDGE is UL Classified for use in one-, two-, three- and four-hour wall assemblies. The EDGE is specified in UL Designs U419, V438, V489, V498, W433, and W440. Its design characteristics result in reduced injuries and increased safety by eliminating 95% of sharp edges found on traditional drywall framing systems.

Strength by Design - A patented triangular lip provides greater increased strength and stiffness. The result: greater wall heights, easier to screw into and a measurably safer product. The EDGE is a truly unique design.

Increased Productivity - Safer, stronger, fewer stripped screws. Saves on Worker’s Comp claims and downtime. The Rolled Edge Steel Safety System makes The EDGE is thesafest & strongest choice, all at no added cost!

UL® Classified - Tested and approved for use in up to 4-hour rated wall assemblies. The EDGE steel framing system is compliant with ASTM standards C645, C754, A653, and A1003.

The EDGE safety framing is offered in four thicknesses to accommodate a variety of drywall framing needs:

1. The EDGE 25 (EDS125-15) has a design thickness of 15 mils (0.0153”) and is an ideal replacement for conventional 25 gauge framing (0.0188”).

2. The EDGE Performance 20 (EDS125-19) drywall stud has a design thickness of 19 mils (0.0188”) and is manufactured from 55 KSI steel. The EDGE™ Performance 20 Drywall Stud System has been independently tested for compliance with AISI standard S220-15: Standard for Cold-Formed Steel Framing – Nonstructural Members. AISI S220 was developed specifically for state-of-the-art nonstructural drywall products – like The EDGE™ Performance 20 System – and S220-15 has been approved for adoption into the 2018 International Building Code (IBC). Should screw pullout values be a consideration, it is suggested that the designer refer to The EDGE™ screw pullout values on page 13.

3. Now available: The EDGE 30 Mil

Information is available regarding The Gypsum Association's requirements for using DW30 product with Abuse Resistant Board.

Shaft Wall Systems

Shaft wall systems are a specific category of interior fire-rated partitions designed to be installed from only one side. Using very few fasteners, Super Stud’s CT shaft wall studs, coupled with gypsum board, tabbed track and J-runner, make safe and secure rated assemblies with up to 4-hour fire resistance. Shaft wall systems were initially developed for high-rise buildings, that needed to have enclosures around vertical chases, stairwells, and elevator shafts: as a lighter alternative to concrete masonry construction. Scaffolding up the inside of these shafts would be expensive and impractical, so every component of the shaft wall system is installed from the inside. CT stud shaft wall systems have been tested with multiple manufacturers of gypsum board liner panels, and can be used in both horizontal and vertical applications. For specific details on manufacturer-specific applications, check with the gypsum company that made the 1″ liner panels and rated sheathing for your system. For information on Super Stud CT studs, see the resources and details below.

A vertical shaft wall system starts at one corner or up against an adjacent column or wall using a vertical segment of tabbed track. At the top and bottom of the wall, either J-runners or tabbed track or J track may be used. The 1″ leg of all tracks should be towards the installer, and the longer leg should be away from the installer. Note that both J-track and tabbed track have their longer leg 2-1/4″ long; J-runner has a 3″ longer leg. All three styles have a 1″ short leg. Against the vertical tabbed track, install 1″ liner panel between the tabs (fold them out, 2′ on center) and the long leg. This should be a nice, tight fit, and this first piece may be held in place with 2 or 3 optional screws. Vertically, the liner panel should be cut up to 1″ shorter than the wall cavity. This will allow it to be lifted in place over the near leg of the bottom track, and still fit in the wall. See specific Underwriters Laboratories (UL) design information for how wide the permissible gap can be at the top of the wall, and what type of fire-caulk must be used to fill this gap. Note that liner panels can have horizontal butt joints; no blocking is required behind these joints in most assemblies if there are no gaps at these joints.

After this first liner panel is in place, a CT stud should be installed over the tapered (vertical) edge of the panel. The “T” side of the CT stud should be on the far side of the wall, away from the installer. It does not matter if the tabbed side of the “T” or the solid side of the 1″ gap goes over the board first: these studs may be installed either way. The important orientation is for the 1″ liner panel and the “T” side of the stud to be on the far side of the wall, and the cavity or “C” side of the stud to be towards the installer. The studs may have either a 3/4″ or 1″ gap at the top, depending upon the UL assembly requirements. Once the CT stud is in place (no screws required in most cases) the next liner panel is slid in place to complete the bracing of the CT stud. This progression of liner panel and CT stud continues to the next corner or the end of the wall. See the below details for options for both inside and outside corners.

CT studs (example: 400CT137-33) |

Tabbed Track & J Track (both 2.25" leg: example 400TT225-33) |

J Runner (3" leg: example 400JT300-33) |

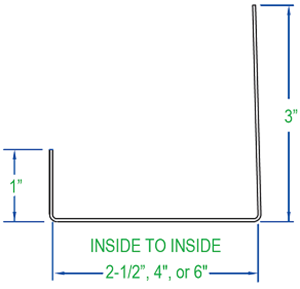

Deep Leg Track

Deep leg deflection track is used at the top of a wall to allow for expected downward movement of the primary structure. A deep leg track accommodates space between the end of the stud and track and allows for deflection. Deep leg track is available in a 2", 2.5" and 3" legs.

ASTM and Code Standards:

Super Stud products comply with the applicable provisions of the following:

International Building Code (IBC) 2006 - 2018

Sheet Steel: ASTM A1003 and ASTM A653

Galvanized Coating: ASTM A653

Members and Tolerances: ASTM C645

Meets ASTM C754 when installed properly in structure

UL designs: U419, V438,V498

3rd Party Certification: Manufacturing verified and inspected by Home Innovation Research Labs, Inc.

All Products

- Clips and Accessories

- Aluminum Breakaway Clips

- Clip Angles

- Cold-Rolled Channel CRC

- Flat Strap

- Furring Channel

- Gusset Plates

- Header Jamb and Cripple Clip

- J L and U-Trims

- Joist Bridle Hangers

- Resilient Channel

- S/HJCT Steel-Joist Connectors

- Simpson Strong-Tie® SUBH

- Solid Blocking

- SuperBead® Drywall Corner Bead

- SuperJoist Blocking

- Utility Angles

- Web Stiffeners

- Z-Furring Channel

- Nonstructural Studs

- Nonstructural Tracks

- Structural Stud and Joist

- Structural Track

- Shaft Wall and Area Separation Wall

- MSDS-SDS and Green Building